Sustainable infrastructure: Little changes can make a big difference

October 28, 2021

When Wake Forest came from Wake Forest, North Carolina, to its current home in Winston-Salem in 1956, sustainable infrastructure was not a topic of conversation.

A good deal of the buildings on campus are still from that era.

However, Wake Forest’s Facilities and Maintenance staff are in the process of renovating campus buildings to be in compliance with the current times. More importantly, they are ensuring that Wake Forest’s carbon footprint does not contribute to the already pressing problem of climate change.

College campuses are major sources of carbon output, with class buildings having to be powered daily and thousands of students to house. But, most students do not know all of the work that is happening behind the scenes to make our campus more eco-friendly and eventually reach carbon neutrality by 2040.

“It is not unusual for students to not understand how everything operates, but it is cool to know how all of these renovations work in favor of the environment,” Lindsay Batchelor, director of the Office of Sustainability, said.

Wake Forest is rethinking its residential buildings and imagining how little and big changes alike can make a major difference in the energy usage of the campus. From Energy Star appliances in newly renovated dorms to the addition of chiller plants on north and south campus, the maintenance and facilities teams are making eco-friendly improvements across Wake Forest.

The first major addition to the campus that has helped lead the university toward becoming more sustainable are the two chiller plants, one behind Luter and the other on the right side of Farrell Hall.

“These plants are responsible for distributing cold water across campus and providing cooling for 80-90% of the main campus,” Jimmy Nifong, assistant director of utilities operations, said. “We also have a newly renovated piping system that delivers this cool water through campus that is rid of lead and other toxins.”

But what is most impressive about the chiller plants, he says, “is how just the north chiller plant alone saved five percent of all of Wake Forest’s electrical power to date.”

The chiller plants work in two ways: saving water and reducing energy. Doug Ecklund, assistant director of Building Systems explains it this way:

“We force the chillers to work harder and they are very efficient,” he said. “The revised piping in some of the buildings is used to force the chilled water through the buildings instead of bypassing and going back to the chilled water plant. This ensures that the water is cold and we are not wasting that energy and warming the water back on its way to the building.”

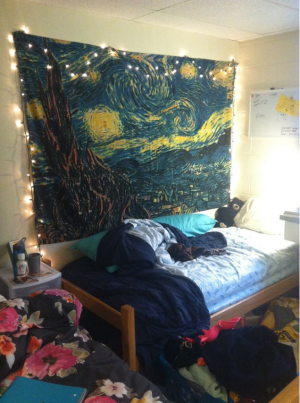

Another way that water is conserved on Wake Forest’s campus is within the dorm rooms themselves. Low-flow sinks and showers have been installed into the Hearn Plaza dorms during their renovations.

“These low flow sinks and showers have not only helped conserve water as a resource, but also reduce energy,” Michael Draughn, assistant vice president for facilities operations, said. “In fact, water consumption has dropped by 50% after the renovations were completed. Using half of the amount of water saves carbon on a global scale.”

He continued: “The lower cost of the energy usage is not the main driver of these additions, it is simply just the right thing to do.”

The most obvious renovation on Wake Forest’s campus in Spring 2022 will be the new and improved Luter Residence Hall. With Johnson and Bostwick following suit after Luter is completed, this residence hall can be a beacon of opportunity for sustainable development at Wake Forest, Draughn said.

“With all the concrete that is in the Hearn Plaza buildings, there was only so much we could do space wise with the physical limitations,” Draughn said. “But with Luter, we have the opportunity to do something better.”

In addition to increasing the dormitory room sizes, new fan cooling units have been put in place in each room instead of the older and energy wasting window cooling units.

“The problem with the old window units was that students would cover them with their blankets and beds, trapping air and moisture that can create mold,” Frank L. Blum, head contractor of the Luter renovations, said. “These new wall fan cool units have better control for dehumidification.”

These fan cool units can also act as a barrier against contaminants and even air-borne diseases such as COVID-19, per Blum.

“There are anti-microbial filtration systems in each of the fan cool units that will filter out any pathogens and particulate matter floating in the air,” Blum said.

However, there is only so much the building itself can do to reduce energy consumption; a good deal of it is left up to the individual students’ behavior.

”As you can see, campus buildings have a lot of opportunities within their infrastructure to save energy and water,” Batchelor said. “But at the end of the day, the user also has that opportunity.”

Ecklund has the following instructions for reducing a carbon footprint:

“Do not leave your window open, turn your lights off, put your thermostat up a few degrees, recycle, and ride the bus instead of having people pile in a car.”

Draughn puts all of the purposes behind these efforts bluntly by saying, “All of the little things students can do, do not affect Wake Forest’s bottom line, but they sure can help minimize our carbon footprint in a positive way.”